Stockout hurts your business and negatively impacts your brand image in the eyes of your customers. Identifying the causes of stockout empowers you to overcome inventory issues and have sufficient stocks to meet demand.

One of the major reasons for regular stockout is incorrect data. Complicated as it may sound, retailers can overcome this by implementing inventory management systems.

Let us look at how to prevent inaccurate data from causing stockouts.

1. Use a Modern Inventory Management System

By implementing a modern inventory system, you can avoid stock discrepancies. Maintaining ledgers or excel spreadsheets is not only time-consuming but also prone to errors.

Modern apps often operate on a cloud-based system, enabling you to manage and edit inventory remotely. In other words, it can automatically modify stock levels when a transaction is made, saving you from manually updating the database. It is also exceedingly beneficial for omnichannel operation.

Today, inventory tracking systems can be integrated into other systems such as point of sale and order management. Moreover, retail point of sale allows you to create order recommendations when stocks go below pre-determined levels. Thus implementing a modern inventory system will provide you with accurate data and help you avoid stockout.

2. Connect Inventory from Different Platforms

Manual management can’t particularly deal with a complex business model. Therefore, you need management software to take care of your real-time inventory. By constantly updating the stock level, it helps you manage your supply chain and avoid being out of stock.

If you’re selling across multiple channels, you should connect all your retail platforms to ensure accurate sync of data whenever a transaction is made. This integration of different points of sales with your e-commerce website is called omnichannel inventory management.

3. Count Stocks Regularly

One of the reasons for a stockout is the discrepancy between the data in your system and the actual stock number. This might be due to human error, technical issues, shrinkage, loss, or theft of goods. Conducting frequent inventory audits will help you avoid stockouts, especially before the peak seasons.

4. Simplify Processes Done by Human

Never forget to examine your staff’s work scope on a regular basis. This helps point out the repetitive tasks that can be automated so that your employees can focus on the bigger picture.

5. Label and Place Inventory Strategically

Labeling the goods using barcodes and RFID ensures a high level of inventory accuracy. RFID technology allows storing and tracking product information in a chip embedded in an item’s tag or packaging. Strategically labeling and placing allow for faster monitoring and search whenever in need. In this sense, marking the stock is probably the best solution for avoiding inventory data inaccuracies.

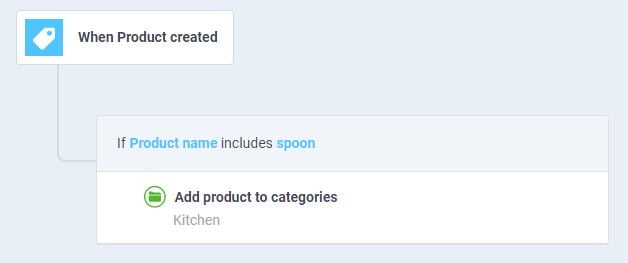

Besides the warehouse, you should also label your product in the backend of your online store. This can be quickly done by integrating Atom8 into your website. All you need to do is set up workflows based on your current business activities. Then whenever the triggers are met, the app will automatically tag products and orders accordingly. In other words, there’s no need to manually look at every item and place a label anymore. You save a lot of time and resources needed for more impactful decisions.

Conclusion

Out-of-stock products not only lead to a loss in the sale volume but also result in poor customer experience. Therefore, effective inventory management techniques are a must to prevent regular stockout.